We specialise in the manufacture, repair, and maintenance of machinery and industrial processes of all types, regardless of size or complexity.

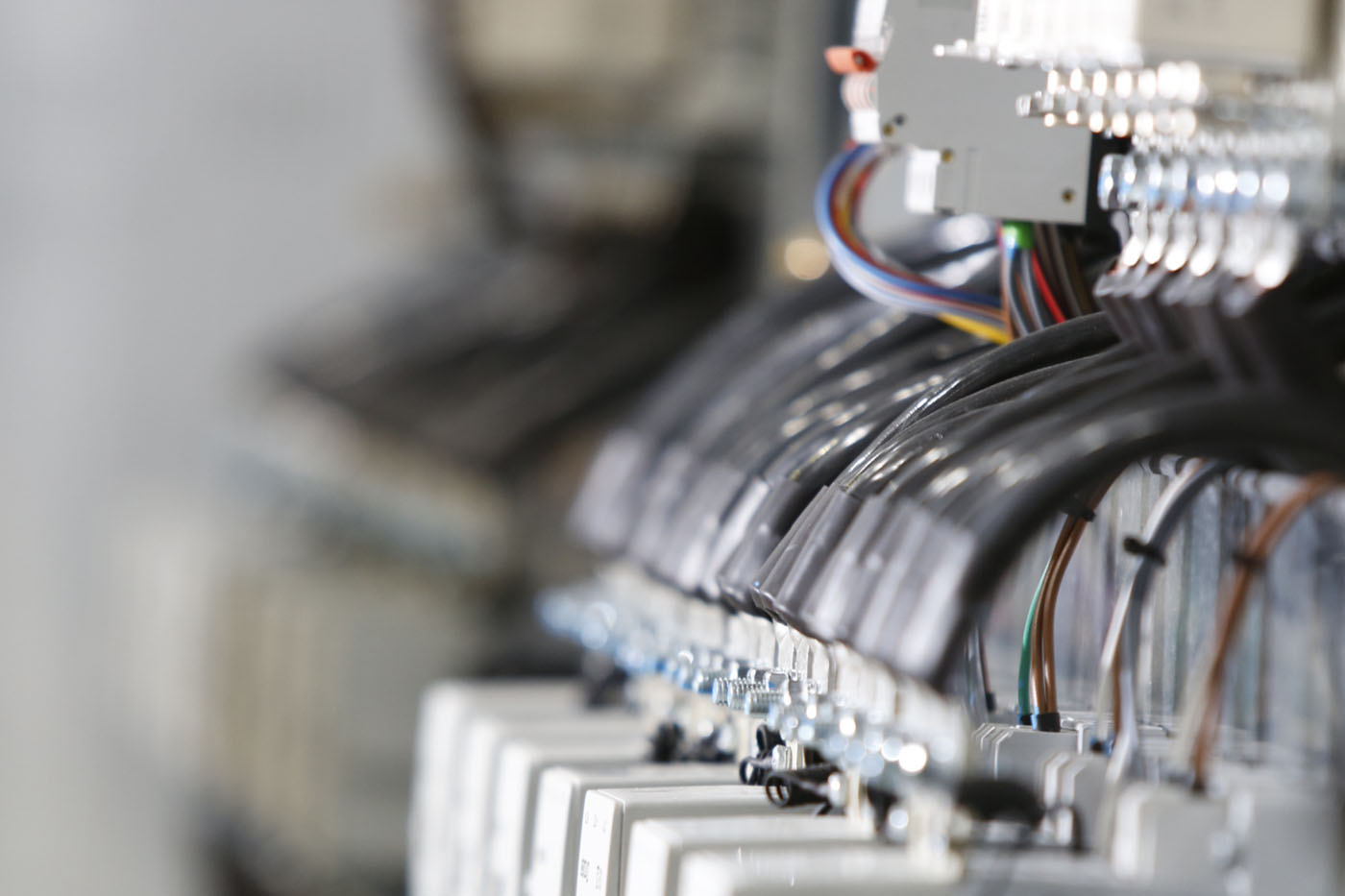

We have a technical department with highly qualified personnel, in constant innovation, who carries out different tasks of assembly, repair, maintenance, and revision in medium and low voltage electrical installations.

We provide comprehensive services covering:

• Preventive and repair maintenance to prevent breakdowns and extend service life.

We manage equipment maintenance work and/or repair, renovations to increase production or new technologies in order to improve the production system in Industrial Shutdowns (24/7 emergency services).

Medium voltage work and maintenance, processing centres, connection and disconnection to the network.

• Industrial assembly

Creation of the initial draft with advice on the technology and material to use.

We execute and assemble installations with leading brands materials to guarantee the quality of the materials, the fulfilment of execution deadlines, and a precise adaptation to the customer’s requirements.

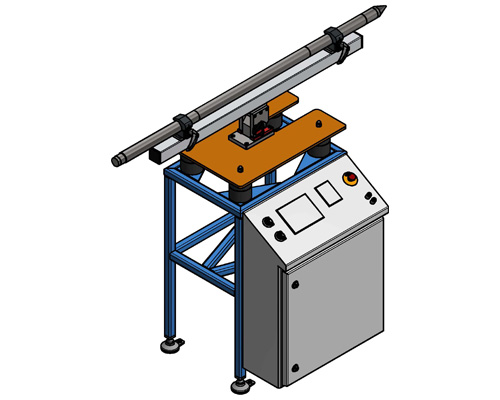

• Automation of industrial processes.

In our workshops, we build electrical power and automation cabinets (see reference E-HOUSE).

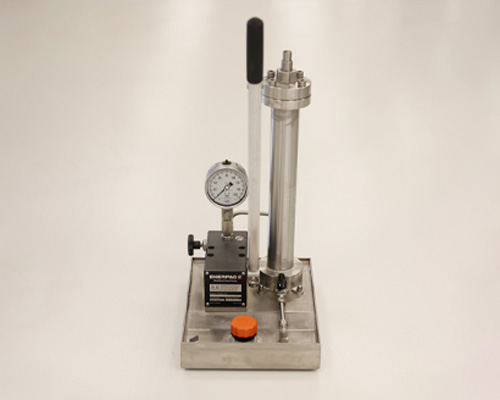

• Explosion proof facilities. We have extensive experience in designing and manufacturing ATEX equipment for zones 0, 1 and 2, being an ismATEX installation company.

• Energy projects (production) both conventional and renewable.

• Low voltage installations.

• Automation and process control.

• Overhead or underground lines for power distribution.

• Premises with risk of fire or explosion.

• Monitoring, control and data acquisition system.